01

01

… for pharmaceuticals and medical devices through the digitization of accompanying documents in a standardized format, to be exclusively electronic in the future.

02

Complex supply chains are prone to disruptions. Their resilience can be increased through better data exchange and the early detection of needs and bottlenecks. This can help avert future supply shortages – especially for medications.

03

The standardized CO2 footprint management aims to enable data exchange for the sustainability assessment of products along their production and supply chain.

Would you like to actively help shape the data space and implement the use cases? Or would you prefer to support our project idea without being directly involved in operations? However you choose to participate in our endeavor, we invite you to be part of our vision.

If you are interested in working with us, feel free to contact our project advisor, Ege Hüsemoglu:

Email: e.huesemoglu@bdi.eu

Phone: +49 0160 986 45 782

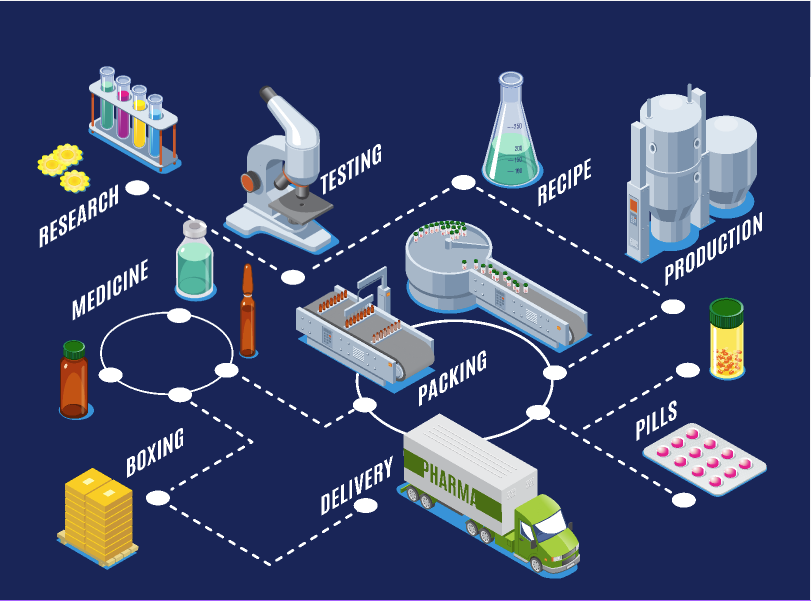

We aim to digitize the production and supply chains of the industrial healthcare sector.

The industrial healthcare sector is a leading, future-oriented industry with high levels of research and innovation. However, digitalization remains underdeveloped in many areas, owing to a lack of interoperable infrastructure that would connect companies across production and supply chains.

HT-X emerged from a group of companies involved in sphin-X, which pursues the vision of creating a collaborative data space for the healthcare system.

sphin-X promotes use cases in the areas of research and development, supply chain, product life cycle, and collaboration.

Over 50 companies and institutions (large healthcare companies, start-ups, SMEs, scientific institutions, and clinics) are involved in the sphin-X project. On November 12, 2024, the sphin-X association was officially founded in Berlin as part of a constitutive meeting. Read more

With Manufacturing-X, industry, policymakers, and academia have launched a joint initiative. The aim is for companies to be able to use data across the entire manufacturing and supply chain in a sovereign and collaborative manner. The Manufacturing-X funding program develops, tests, and demonstrates various cross-sector use cases for a collaborative data space in Industry 4.0, all on a shared technological foundation.

Within the framework of Manufacturing-X, companies from all sectors can network to collaborate across digital data ecosystems. The overarching goal of Manufacturing-X is: One set of standards – one development environment – one operating environment!

In Germany, Manufacturing-X is supported by the Federal Ministry for Economic Affairs and Climate Action (BMWK) through an accompanying funding program, providing initial financing for the necessary research and development efforts.

Would you like to stay up to date on the latest developments, technical advancements, and innovations in the healthcare industry? Sign up for our newsletter now and learn more about creating the technical prerequisites for data exchange, building a data ecosystem, integrating additional participants into the data space, and much more.

Senior Manager

HealthTrack-X